Dry Film Storage Management Nitrogen Cabinet

BM1113-3, BM1113-4

Smart RFID Temperature Monitoring Cabinet for Dry Film

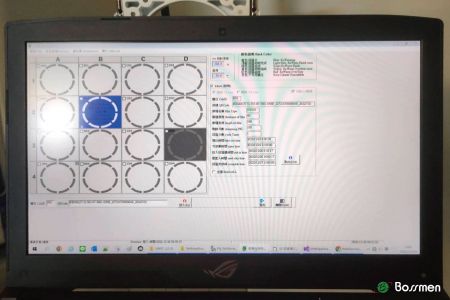

The Dry Film Storage Management Nitrogen Cabinet combines advanced RFID technology and precise humidity control systems for intelligent storage. Designed for environments that require strict humidity control and efficient item management, it uses RFID tags for tracking and management, ensuring data accuracy and real-time updates. This cabinet precisely controls internal humidity to avoid fluctuations that could negatively affect the items, maintaining them in optimal storage conditions. It calculates the dry film's insertion time and estimates the rewarming completion time, notifying users when it's done. A light indicator system helps track dry film status, with red for expired, green for completed, and blue for near expiry, aiding in effective management of multiple films.

The Dry Film Storage Management Nitrogen Cabinet not only improves storage efficiency but also reduces manual management costs, enhancing overall operational efficiency. Through an intuitive management interface, users can easily monitor the humidity status of each storage unit, ensuring high-precision item storage and tracking, providing a more efficient management approach for your workflow.

Features

- Material and Design: Made of stainless steel SUS 304 with a glossy finish, featuring high-load stainless steel film racks inside the cabinet. The cabinet door has a round glass window, allowing users to easily and intuitively check the dry film indicator light status. Equipped with anti-slip rubber feet for enhanced stability, preventing vibration or sliding.

- Precise Humidity Control and Monitoring System: Humidity can be precisely set within the 30% RH range, offering flexible operational range. The system is equipped with high-precision temperature and humidity sensors, accurately monitoring and displaying current status through an LED digital display, ensuring operators can always check the equipment's condition.

- Energy-saving Nitrogen Drying Technology: Once the set humidity level is reached, the system automatically stops nitrogen release, further saving gas consumption.

- Buzzer Flashing Alarm: The system can be set to emit a buzzing sound and flash the panel when humidity or other environmental parameters are abnormal, alerting users to take timely action.

- Panel Locking Function: Prevents accidental operation, ensuring stability and security of the equipment settings.

- Offset Calibration Function: Users can calibrate sensors or equipment data to ensure the accuracy of measurement data.

- Material Sensing Feedback: The indicator light displays whether materials are placed inside, helping users monitor the equipment's operational status.

- Door Opening Abnormal Alarm: An alarm sounds if the door is left open too long or opened abnormally, prompting operators to address the issue and preventing prolonged operation in abnormal conditions.

- Equipped with a warning light: The layered warning light is commonly used to indicate the operating status of machinery or equipment. For example, a green light indicates normal operation, a yellow light indicates a warning or something that needs attention, and a red light indicates a malfunction or the need for immediate action.

Benefit

- Significant Nitrogen Consumption Savings: When the preset humidity level is reached, the system automatically stops the nitrogen release. If the humidity exceeds the set value, the system activates to adjust the airflow. This design significantly reduces nitrogen consumption, helping businesses save costs.

- Highly Customizable Design: Tailored to different needs, offering a variety of Dry Film Storage Management Nitrogen Cabinet options in terms of storage capacity and cabinet structure, providing the best storage solution for various scales and production environments.

- Smart RFID Management: Built-in RFID technology automatically identifies and tracks the status of items, enabling efficient and error-free item management, improving the convenience of storage and retrieval.

- Improved Operational Efficiency: Reduces manual intervention and error risks through an automated monitoring and management system, making operations more efficient and accurate, thereby saving time and costs.

Product Specifications

| Model | Dry Film Storage Management Nitrogen Cabinet BM1113-3 | Dry Film Storage Management Nitrogen Cabinet BM1113-4 |

|---|---|---|

| External Dimensions (mm) | W1620 x H1780 x D870 | W1300 x H1972 x D800 |

| Stored Contents | Dry Film (16PCS) | Dry Film (16PCS) |

| Temperature Display | 0°C ~ 60°C (± 1°C) | 0°C ~ 60°C (± 1°C) |

| Humidity Control Range | <5%RH (± 3%RH) | <5%RH (± 3%RH) |

| Compatible Products | None | Equipped with a Side-Mounted 17" Panel PC |

| Voltage | 110V/220V | 110V/220V |

| Frequency | 50Hz/60Hz | 50Hz/60Hz |

| Power Consumption | 16W | 16W |

- Gallery

- Dry Film Storage Cabinet has precise sensors for real-time monitoring and LED display for easy status check.

- Nitrogen Cabinet auto-stops inflating when humidity is set, adjusts airflow if humidity exceeds set value.

- BM1113-3 Dry Film Storage Management Nitrogen Cabinet.

- Cabinet with RFID for efficient, error-free item tracking.

- Users can calibrate sensors for accuracy.

- The indicator shows material status.

- Related Products

Dry Film Storage Management Nitrogen Cabinet

BM1113-3, BM1113-4

The Dry Film Storage Management Nitrogen Cabinet combines advanced RFID technology and precise...

DetailsRFID Item Management Refrigerator

BM1113-7

RFID Item Management Refrigerator is an intelligent storage device combining advanced RFID...

DetailsSolder Paste Ambient Temperature Recovery Cabinet

BM1149

The Solder Paste Ambient Temperature Recovery Cabinet is specifically designed for solder paste...

DetailsPhotoresist Ambient Temperature Recovery Cabinet

BM1149-4

Photoresist Ambient Temperature Recovery Cabinet ensures optimal ink condition during storage...

DetailsDry Film Ambient Temperature Recovery Cabinet

BM1151

The Dry Film Ambient Temperature Recovery Cabinet is designed for the storage and temperature...

DetailsWindowless Dry Film Recovery Cabinet

BM1278-3

The Windowless Dry Film Recovery Cabinet is designed for precise dry film recovery. It uses...

DetailsRFID Dry Film computer desk

BM4010

This system scans the QR code on the dry film and pairs it with the RFID tag for precise product...

Details

Dry Film Storage Management Nitrogen Cabinet – Precision Humidity Control by BOSSMEN

The Dry Film Storage Management Nitrogen Cabinet is designed to protect sensitive materials, electronics, and instruments from moisture damage. BOSSMEN integrates advanced humidity control systems to maintain stable RH levels, ensuring reliability in manufacturing, laboratories, and research facilities.

Engineered with precision and durability, the Dry Film Storage Management Nitrogen Cabinet offers consistent performance for long-term storage and process environments. From cleanrooms to quality labs, BOSSMEN products help users reduce corrosion, oxidation, and ESD risks while maintaining compliance with strict environmental standards.

Discover how the Dry Film Storage Management Nitrogen Cabinet enhances productivity and preservation in your workflow. Each unit reflects BOSSMEN’s thirty years of humidity control expertise, combining innovation, safety, and measurable value for industrial and laboratory applications.