Nitrogen Control System (Oxygen Monitoring Equipped)

N2HTO

Gas Concentration Control System, Oxygen Concentration Monitoring System

Nitrogen Control System (Oxygen Monitoring Equipped) is designed to precisely control oxygen levels, reducing oxygen concentration to maintain the required nitrogen levels. Ideal for industries like semiconductor manufacturing, electronics, biotechnology, and medical equipment, it ensures a stable environment and product quality. The system offers real-time monitoring and alarms to quickly respond when oxygen levels exceed set limits, preventing issues and damage.

Features

- Built-in memory can store up to 11,900 temperature and humidity records.

- Data collection interval can be set from 1 to 240 minutes.

- Supports detailed time settings including year, month, day, hour, and minute.

- Data can be downloaded to a computer via RS232 interface, with support for viewing in Excel, PDF, and other formats.

- Displays both temperature and humidity curve graphs and data tables simultaneously.

- Provides temperature and humidity offset calibration and panel lock functions for more flexible operation.

- Equipped with an intake ion nozzle to effectively eliminate static electricity, prevent dust adhesion, and ensure a clean environment while protecting instruments and materials.

- Allows setting upper and lower temperature and humidity limits, with alarms triggered if limits are exceeded.

- Provides flashing warning lights or buzzer alarms to ensure immediate response to abnormal conditions.

- Sensors can be separated from the display and detected up to 150 meters away.

Application

- Electronics Manufacturing: In the production of semiconductors, LCDs, photovoltaic products, and other high-precision electronics, controlling oxygen concentration is crucial. Excess oxygen can cause oxidation or damage to materials, affecting product quality and performance. The Nitrogen Control Unit provides a stable low-oxygen environment, reducing oxidation and static issues.

- Chemical Processes: Many chemical reactions are highly sensitive to oxygen levels, and excessive oxygen can interfere with reactions or cause unwanted by-products. The Nitrogen Control Unit offers stable nitrogen control in these processes, effectively suppressing oxygen’s impact, ensuring reaction stability and efficiency.

- Medical Field: In some medical devices and pharmaceutical manufacturing processes, oxygen concentration must be controlled to maintain product stability. For example, excessive oxygen in drug production can alter the chemical structure or reduce efficacy. The Nitrogen Control Unit provides a low-oxygen environment to protect drug quality.

- Metal Refining and Welding: In metal refining, welding, and heat treatment processes, nitrogen is used to replace oxygen, preventing metal surface oxidation or coating damage. For example, nitrogen can be used in steel or aluminum alloy heat treatment to avoid the adverse effects of excessive oxygen on the metal surface.

- Optical Manufacturing: In the production of optical lenses and laser equipment, controlling oxygen concentration is key. Nitrogen is used to create a low-oxygen environment to prevent lens surface oxidation, ensuring the high quality and stability of optical components.

- Aerospace: The Nitrogen Control Unit plays an important role in spacecraft environmental control, particularly in the gas environment of spacecraft. To prevent oxygen from damaging internal equipment, nitrogen is typically used to replace oxygen, creating a stable working environment.

- Fuel Cell Technology: In fuel cell research and manufacturing, controlling oxygen concentration is critical for reaction efficiency and longevity. The Nitrogen Control Unit ensures the proper oxygen environment, enhancing fuel cell performance and lifespan.

- Laboratories and Research: In precision experiments and research processes, a low-oxygen environment is needed for special tests, such as material testing and catalyst studies. The Nitrogen Control Unit provides a stable nitrogen environment for these experiments, preventing oxygen interference with results.

The Nitrogen Control Unit is primarily used in these applications to reduce or eliminate oxygen concentrations in the environment, preventing oxidation, degradation, or other oxygen-related negative effects, ensuring product quality, improving process stability, and protecting equipment from damage.

Product Specifications

| Model | Nitrogen Control System (Oxygen Monitoring Equipped) N2HTO |

|---|---|

| External Dimensions (mm) | W315 x H337 x D220mm |

| Display Screen Numbers | 2.3" LED Digital |

| Humidity Control Range | Adjustable from 1% RH to 60% RH |

| Humidity Display Range | 0.0%RH ~ 99.9%RH |

| Temperature Display Range | 0.0°C ~ 60.0°C |

| Temperature Accuracy | ± 1°C (0 ~ 60°C) |

| Humidity Accuracy | at 25°C ± 3%RH (1 ~ 60%RH) |

| Oxygen Concentration Display Range | 0.1% ~ 25% |

| Oxygen Concentration Accuracy | ± 0.2% (0 ~ 25%) |

| Inlet Pressure | Nitrogen, 3kg/cm² ~ 7kg/cm² |

| Voltage | 110V ~ 220V / 50Hz ~ 60Hz |

| Power Consumption | 25W |

- Gallery

- Related Products

Temperature and Humidity Monitoring Unit

2HTDP, 4HTDP, 7HTDP

The Temperature and Humidity Monitoring Unit is specifically designed for storage and production...

DetailsSlimline Nitrogen Control System

FN2HT, FN2HT-FM

The Slimline Nitrogen Control System is designed for environments requiring precise nitrogen...

DetailsNitrogen Control System (Oxygen Monitoring Equipped)

N2HTO

Nitrogen Control System (Oxygen Monitoring Equipped) is designed to precisely control oxygen...

DetailsStandard Nitrogen Control system

N2HT

The Bossmen Standard Nitrogen Control Unit is designed specifically for the semiconductor industry,...

DetailsCDA Control system

RAD01

The CDA Control system is designed for the electronics industry, providing clean, dry air for efficient...

DetailsTemperature, Humidity & CO2 Monitoring Unit

2HTCDP

Our Temperature, Humidity & CO2 Monitoring Unit is designed for various applications, providing...

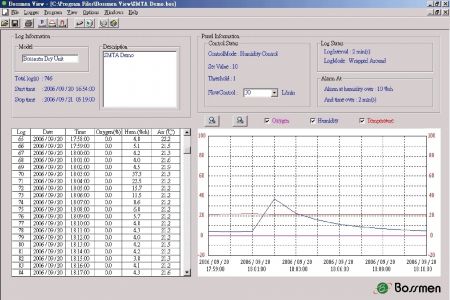

DetailsTemperature and humidity monitoring software

Bossmen View

Our temperature and humidity environment monitor is specifically designed for applications...

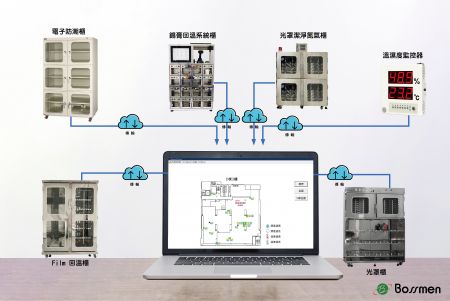

DetailsIoT temperature and humidity monitoring system

Bossmen View Server

Bossmen IoT temperature and humidity monitoring system can monitor all temperature and humidity...

Details

Nitrogen Control System (Oxygen Monitoring Equipped) – Precision Humidity Control by BOSSMEN

The Nitrogen Control System (Oxygen Monitoring Equipped) is designed to protect sensitive materials, electronics, and instruments from moisture damage. BOSSMEN integrates advanced humidity control systems to maintain stable RH levels, ensuring reliability in manufacturing, laboratories, and research facilities.

Engineered with precision and durability, the Nitrogen Control System (Oxygen Monitoring Equipped) offers consistent performance for long-term storage and process environments. From cleanrooms to quality labs, BOSSMEN products help users reduce corrosion, oxidation, and ESD risks while maintaining compliance with strict environmental standards.

Discover how the Nitrogen Control System (Oxygen Monitoring Equipped) enhances productivity and preservation in your workflow. Each unit reflects BOSSMEN’s thirty years of humidity control expertise, combining innovation, safety, and measurable value for industrial and laboratory applications.